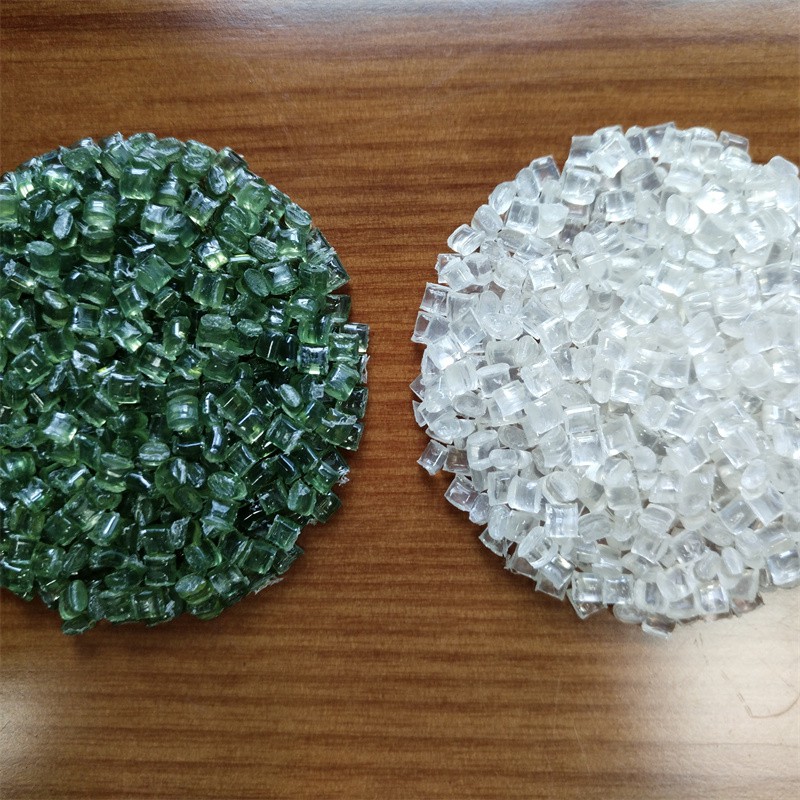

PC Plastic Particles

High impact strength, shape stable, colourless, transparent, easy dying,

electric insulation, corrosion resistance, wear resistance are good.

However, poor self-lubricating, with tendency to stress cracking, high

temperature easily hydrolyzed, poor compatibility with other resins. PC

is suitable for making instrument small parts, insulating and

transparent parts and impact-resistant parts.

PC usually is made into products by injection molding, extrusion,

cotining, blow molding, thermoforming, printing, adhesive, coating and

machining, the most important processing method is injection molding.

1. PC is made into large bulb shade, protective glass, the right and

left eyepiece tube of optical instruments. Also, it is used as the

transparent materials in plane.

2. PC is good insulation, made into insulated connector, coil frame,

tube socket, insulating sleeve, telephone housing and parts, miner's

lamp battery shell. Also, it is used to make fine parts of communication

equipment, such as CD-ROM, telephone, computer, video recorder,

telephone switches, signal relay. The PC film is used for capacitors,

insulation foreskin, recorder, color video tape. etc

3. Machinery and equipment-PC is suitable for gear, rack, worm,

bearings, cams, bolts, crank, ratchet, also suitable for machinery and

equipment housings, covers and frames.

4. PC can be made into cap, tube, bottle and dental equipment, drug

containers and surgical instruments. Even be used as an artificial

kidney, artificial lung and other artificial organs.

5. For architectural, PC can be made into Double-wall hollow bars, glass

of greenhouse. For textile industry, PC is suitable for making bobbin,

textile machine bearing. For daily, PC is good material can be made into

tableware, toys and models.