.png)

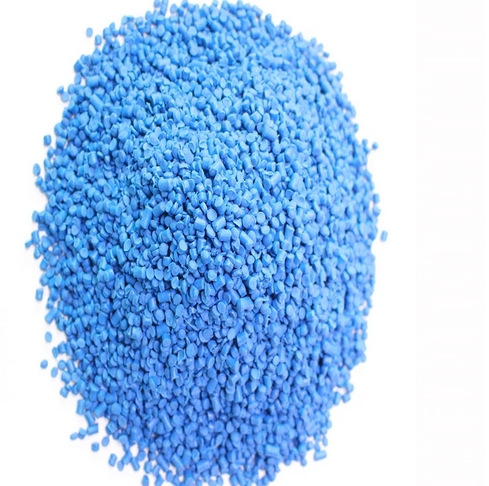

Recycled Plastic Particles

Softeners have expansion and plasticizing effects, and commonly used ones include coal tar, pine tar, petroleum based softeners, and cracked residue. Activators can shorten the regeneration time and reduce the amount of softeners used.

Softeners have expansion and plasticizing effects, and commonly used ones include coal tar, pine tar, petroleum based softeners, and cracked residue. Activators can shorten the regeneration time and reduce the amount of softeners used. The commonly used activators are aromatic thiols and their zinc salts, as well as aromatic disulfides.

The production process of recycled rubber includes three steps: crushing, regeneration (desulfurization), and refining.

In addition to this traditional regeneration method, a new method for utilizing waste rubber is being developed by freezing and crushing waste rubber into rubber powder with different particle sizes, which can be directly used as a rubber filler.

prev:

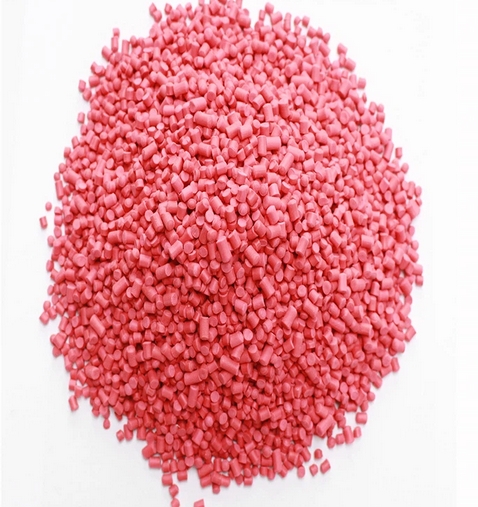

LLDPE Plastic Particles

next:

no data